SUPREME CSM-430GA-01/02 Electronic, High-speed, Bartacking Sewing Machine

Features a precise thread cutting system which reduces thread nesting. Integrated (no belt) servo motor insures silent high speed sewing and low power consumption. The user can program various bartacking and contouring stitches in an 40×30 mm area. Performs perfectly on wide variety of fabrics. 01 variation is used for medium thickness material. 02 variation is used for thick material (denim, bags).

This machine is an analog to Brother KE-430D.

Maximum Speed: 3,200 rpm. Since a direct drive system is used, startup and stopping is quick.

Positioning Carried Out Quickly and accurately since the operation of the work clamp lifter is controlled by a pulse motor, the work clamp lift amount can be set in two steps. Positioning is easy, and the time for setting up the material to be sewn is reduced. In addition, the pedal operates smoothly with light pressure, and excellent response is obtained when the pedal is repeatedly depressed. The work clamp operates quietly when it lowers, so that operation gives less stress.

Work Clamp Lift Amount Is Automatically changed according To The Program clean Sewing it is a semi-dry type where only clean oil is supplied to only the hook. Since no oil is used around the

needle bar and thread take-up, so you can use the sewing machine with no worry about oil staining. Because the direct drive system is used, sewing products will not be stained by belt shavings. The maximum work clamp lift amount and the intermediate work clamp lift amount (positioning) can be set without using tools by inputting numbers into the panel. In addition, if it is set to user program mode, the work clamp lift amount can be set for each program, so work is always done at the optimal height. You do not need to adjust the work clamp lift amount each time the program changes. Naturally, it can also be set for cycle sewing.

Since a feed mechanism and needle bar and thread take-up mechanism with high rigidity have been adopted, there is no slack or bending of the mechanism even with high speed sewing. In addition, since the feed mechanism uses a servo controlled pulse motor, the pattern does not lose its shape even with high speeds and heavy sewing materials. Since the data is resolved at 0.05 mm per pulse for the feed, slanted lines and curves are beautifully, accurately and smoothly completed.

A servo-controlled feed mechanism with high rigidity and a needle bar and thread take-up mechanism with optimized timing and stroke have been adopted, so that it is possible to sew at low tension without variation in upper and lower thread tension. The range of thread tension balance has been expanded, and the range of thin materials and knit applications that can be sewn has expanded.

To minimize the thread trailing length, a special movable knife and fixed knife are used, and the fixed knife has been placed close to the fabric. The thread trailing length at the back of the material after trimming is 2 – 2.5 mm, so that manual thread trimming is unnecessary. (-1 and –7 specifications).

The upper thread nipper securely holds the upper thread for the first stitch underneath the fabric. This prevents upper thread cast-off (no skipped stitch) even through there is no reduction in speed at the beginning of sewing. It is also possible to shorten the needle thread remaining after trimming, preventing bird’s nests and stains on the thread at the beginning of sewing operation.

It is a semi-dry type where only clean oil is supplied to only the hook. Since no oil is used around the needle bar and thread take-up, so you can use the sewing machine with no worry about oil staining. Because the direct drive system is used, sewing products will not be stained by belt shavings.

A powerful 550 W servo motor has been adopted. The needle penetration force is powerful even at low speeds, and there is plenty of power available for sewing thick materials.

A high rigidity frame is used. Each part, down to the most detailed, is balanced using the most up-to-date computer analysis, so that noise and vibration are reduced to their utmost limits. Operators do not tire and do not feel stressed.

If you have any questions or wish to know the price please inquire via email: info@siuvimostilius.lt , phone +370 5 2733035 or press a button ‘Inquire’ and fill up a form.

| Model | SP-430GA-01/02 |

| Application | Electric Bartack (Bartacking) Machine |

| Line | Single-needle flat seam |

| Highest sewing speed | 3,200 rpm |

| Sewing area | 40×30 mm |

| Cloth feeding device | Intermittent feeding (driven by pulse motor) |

| Stitch Length | 0.05 – 12.7 mm |

| Maximum stitch amount | 5000 stitches/1 pattern |

| Presser lifter mode | Pulse motor drive |

| Rising amount of intermittent foot presser | Max. 17 mm |

| Hook | Semi-Rotary standard shuttle hook |

| Electronic wire clamping device | Yes |

| Thread Wiper | Yes |

| Thread clamping device | Yes |

| Cutting device | Yes |

| Data storage method | Flash memory |

| External data storage media | CF card |

| Number of cycle programs | 30 cycles (50 programs for each) |

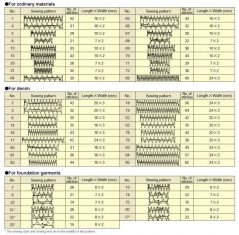

| Number of stored data | 89 kinds of sewing patterns |

| Motor | AC servomotor 550 W |

| Weight | Head: about 64 kg; Table&stand: about 30 kg; Control Box: 20kg |

| Power | Single phase 220 V, 3-phase 380 V |

| Air pressure | 0.5 Mpa 1.7 L/min |

| Analog | Brother KE-430D |

| Needle type | DPx17 |